Read About Dental and Medical

3D GRAPHY DENTAL & MEDICAL is a division of the 3D Graphy platform for 3D printing and 3D visualization training, education, research, events, and service in dental...

Read About Engineering and Industrial Manufacturing

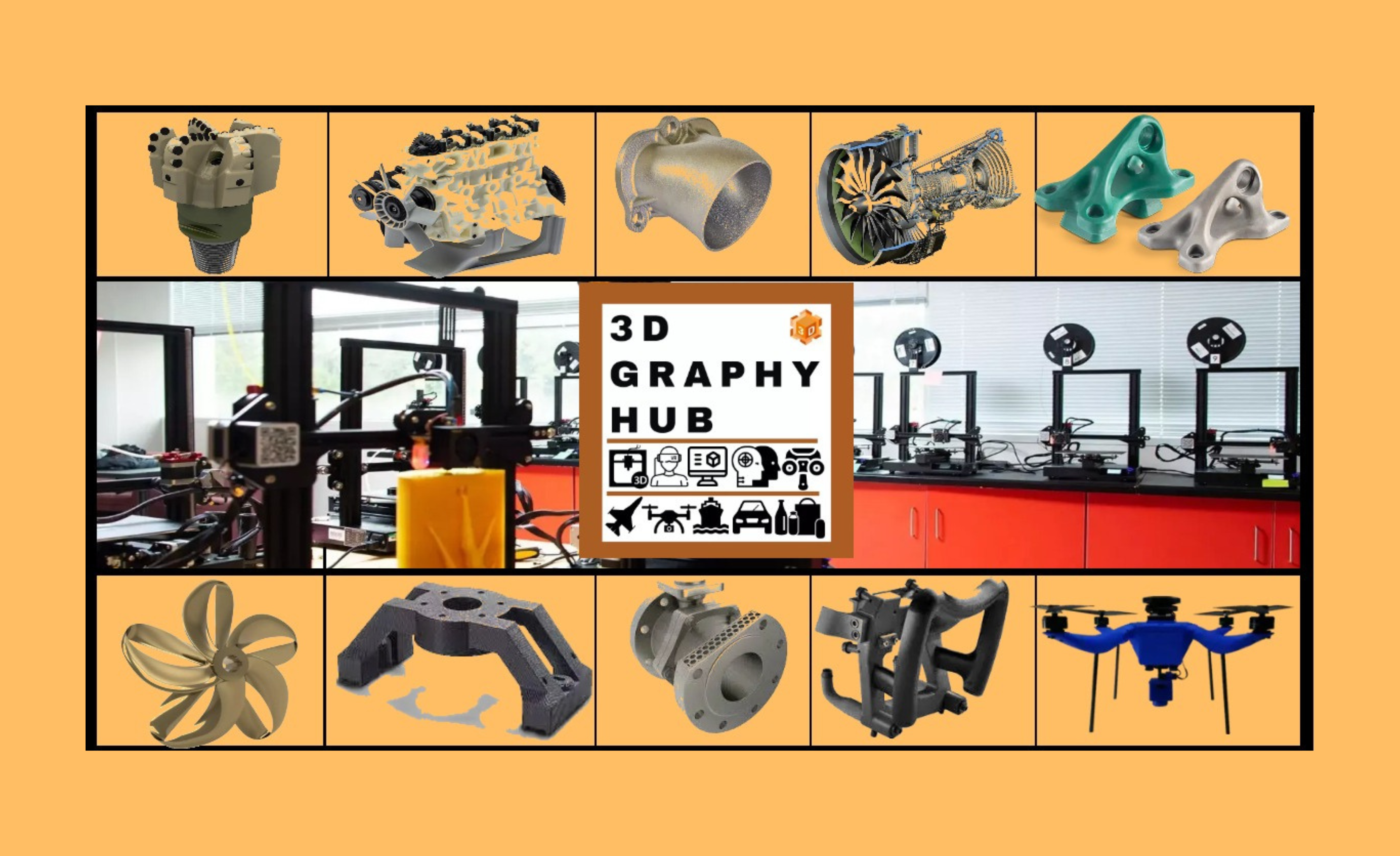

3D GRAPHY ENGINEERING & INDUSTRIAL MANUFACTURING is a division of the 3D Graphy platform for 3D printing & 3D visualization training, education, research, events, and service in aerospace, defense, automotive, oil and gas , shipbuilding, drones and more

Best Buy 3D Products

3D technologies will currently include 3D printers for different applications, 3D scanners, 3D Software’s, 3D visualisation products – Augmented reality, Virtual reality...

3D Technology News For All

3D GRAPHY NEWS, with an international outlook serves as an information medium with its credit line “3D Technology News For All..

3D Technologies we Promote

3D Printing

Printing in three dimensions is innovative.

3D Scanning

Captures physical objects to create precise digital models.

3D Printable Materials

Versatile, durable, and customizable

3D Visualization

Creating immersive, realistic representations

What is 3D Printing and 3D Visualisation?

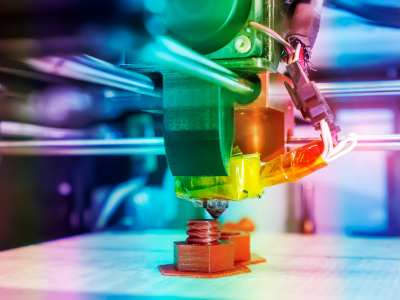

3D printing is also called additive manufacturing.

The first step is to make a virtual 3D design with 3D modelling or get a 3D file through 3D Scanning by reverse engineering of a desired object, in medical it is obtained through the CT or MRI file of the patient. Dental through Intraoral scanner, Prosthetics through hand held scanners etc. And similarly for engineering or machine components it is either by getting a 3D Design or a scanned image of the part to be converted to an STL file directing it to the 3D printer to create the object layer by layer. It is a process of making 3D objects using plastic, metal and composite materials. There is a great deal of R & D going into the various materials to ensure it can be used for various requirements. For medical sector the material is biocompatible and approved by CDSCO, FDA and other regulatory agency. Similarly for Aerospace and Defence the parts are certified by CEMILAC, DGQA and DGCA. 3D Printing serves as a boon for making customized solutions in Aerospace, defense, Automotive, Energy, dentistry, Medical Devices, orthodontics, etc. It is estimated that the global 3D printer and the service market for engineering and medical will grow at a CAGR of 29.8% during the period 2024

2028.

3D Visualisation consist of technologies like Augmented reality , Virtual reality (VR), Mixed reality ( MR) including Extended reality ( XR) and Digital twin to create Digital

Inventory which can be used for selective 3D Printing of parts.

3D Visualisation is a revolution in the medical and health care field. Innovation and technology have increased the scope of several medical centers and hospitals. The

prime ways that reflect the extended reality are augmented, virtual, and mixed reality and these are helpful in the betterment of healthcare centers. This reality enables surgeons to look beyond the human body and check the organs

thoroughly. The technology allows them to reach even the smallest part of the body

and study that via X-rays and 3D structures. It is also helpful in teaching other students and increasing their retention power. Many AI start-ups help in visualizing

and diagnosing the human organs. Thus the extended reality has been an immense support in the medical field and also empower the young generation to provide the

betterment in everyone’s life. 3D Visualisation is also a great tool for Engineering & Industrial manufacturing on similar lines for better planning and execution.

About 3D Graphy

3D GRAPHY LLP is a company promoting 3D technology in India for a decade educating engineers, entrepreneurs, dental and medical professionals to benefit from the technology. It was inaugurated by the former minister for Industries in 2018 supported by 18 different industry associations and government institutions. The focus in promoting 3D Printing & 3D Visualisation amongst all the sectors and specialisation.

Currently the 3D technology we promote includes 3D Printing, 3D Scanning, 3D Imaging, 3D Design, 3D Modelling, 3D Software, 3D Simulation, 3D Printable materials – ( metal, polymer, resins, other biocompatible bone base materials, resin etc), 3D Visualisation – Augmented, Virtual reality, Mixed reality & Digital Twin.

3D Graphy Associate Corporate Members

3D Graphy Industry Association Partners

Apply to our Membership and Training

3D Graphy News

3D GRAPHY NEWS, with an international outlook serves as an information medium with its credit line “3D Technology News For All”. It is one of the first comprehensive 3D Technology Online media news which apart from 3D technology companies will cover all the 3D World news in 3D printing, 3D Scanning, 3D Imaging, 3D Design, 3D Modelling, 3D Software, 3D Simulation, 3D Printable materials ( Polymer, Metal, Resin, Bioink others) , 3D Visualisation – AR, VR, MR and Digital Twin.

Our Platforms

3D Graphy Events

3D Graphy Membership

3D Graphy Hub

Testimonials by Our Clients

Discover what our clients have to say about their experiences

3D Graphy Blogs

- All

- Uncategorized

About MUHS Nasik : The state Government of Maharashtra has established and incorporated an independent University of the health Sciences for the purposes of ensuring proper and systematic instruction, teaching, training and research in modern medicine and Indian system of medicine in the State of Maharashtra and to have balanced growth in the medical sciences so also in uniformity in various courses in medical faculty in the State,…

The National Centre for Additive Manufacturing (NCAM) is envisaged to build a comprehensive ecosystem of additive manufacturing in India by enabling the adoption of additive manufacturing in the industry, prototyping new products and focusing on indigenization, access to state of art infrastructure, enabling research and development of standards and new product development, and promoting skill development activities to generate quality manpower. 3D Graphy LLP a 3D technology group…