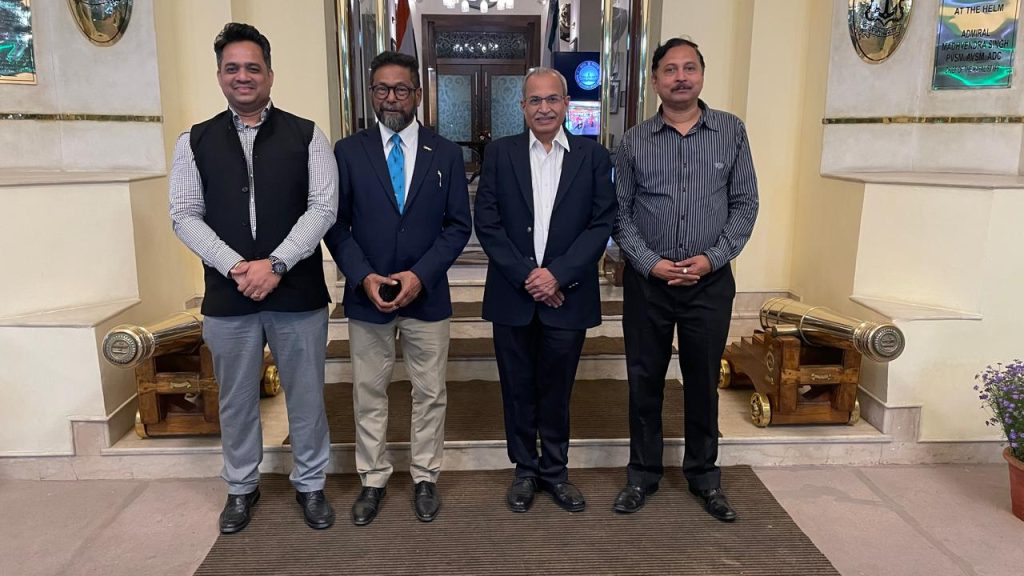

3D Graphy Associate Corporate Member & Team

Dr. Shibu John, CEO & Founder, 3D Graphy LLP, Founder & Secretary, 3DPERA, Mr. Pulak Sen, Founder & Secretary, MRO Association of India, Associate Director, Aviation & MRO, 3D Graphy, Mr. Saroop Chand, Managing Director, Adroitec Information Systems Ltd and Cmde. Niranjan Khardenavis, ( Retd.) Ex- CTO, Indian Navy, Associate Director, Defence & Marine, 3D Graphy. Adroitec Information Systems is a 3D Graphy Associate Corporate Member Adroitec Engineering Solutions (P) Ltd is an Global Engineering Solutions provider with state-of-the-art development centers in India and a 100% owned US based subsidiary HOPE Consulting Inc. With a team of over 300+ highly qualified and experienced professionals, Adroitec delivers services which are closely aligned with the design-through-manufacturing strategies of its global manufacturing customers, crashing cycle times and reducing costs. Adroitec drives to stay at the forefront of technology, and its track record of excellence make Adroitec ideally suited to be the ‘Right Consulting Partner’. •Pioneers in Engineering Solutions since 1988. •Global Consulting & Services for Mechanical / AEC/ KBE since 1993. •200+Qualified & Experienced professionals, engineers & technology experts with more than 1000+ man years of experience. •Global clientele spanning Europe, US, and India. •6000+ customer , 800+ technical institutions Specialties KBE Using Design Automation, PLM / PDM Consulting, CAD/CAM/CAE, Robotics, 3D Printing, 3DM Technical Services, Illustration, ANSYS, Creo Parametric, Windchill, AutoVue, Oracle Primavera, Oracle Unifier, Service Manual, Animation, IronCAD, Moldex3D, GoldFire, IHS Goldfire, IHS EWB, BOM Intelligence, Oracle Prime, and CFD

3D Graphy Associate Corporate Member & Team Read More »

3D Graphy Associate Corporate Member : Imaginarium

Dr. Shibu John, CEO & Founder, 3D Graphy, Cmde. Niranjan Khardenavis, ( Retd.) Ex- CTO, Indian Navy, Associate Director, Defence & Marine, 3D Graphy, Mr. Amod Satarkar, Business Head, Imaginarium, Mr. Ashwani Sharma, Chairman, Aeronautical Society of India, Associate Director, Aerospace, Aviation & MRO, 3D Graphy Imaginarium is the leader in advanced digital manufacturing technology, housing the largest set up of 3D printers in the country. Pioneering game-changing applications for over 50 industries, Imaginarium has disrupted the manufacturing sector by providing a complete ecosystem from conceptualisation to end-use product, enabling enterprises to design better and realise products faster. We are grooming the next breed of makers and innovators for another manufacturing revolution. 3D Graphy LLP is a company promoting 3D technology. And Imaginarium as a member will be will get to promote their products and service through different platforms 3d graphy has constituted in India.

3D Graphy Associate Corporate Member : Imaginarium Read More »

3D GRAPHY KNOWLEDGE FORUM : ” 3D Printing in Electronics & Semiconductors ” A Session introducing the technology to Military College of Telecommunication Engineering, Mhow.

Military College of Telecommunication EngineeringMhow Brig Rajesh VermaHead of Electronics,Military College of Telecommunication EngineeringMhow 3D GRAPHY KNOWLEDGE FORUM – presentation on 3D printing in electronics and semiconductors was presented to Brigadier Rajesh Verma, Head of Electronics at the Military College of Telecommunication Engineering in Mhow, as a demonstration of the potential of 3D printing in advancing military technology. The meeting was initiated by Cmde. Niranjan Khardenavis ( Retd.) Ex- CTO, Indian Navy, Associate Director, Defence & Marine, 3D GRAPHY LLP. Members who joined included Dr. Sankha Dip Das, Scientist “E” , Ministry of Electronics & Information Technology, Govt. of India, Dr. Shany Joseph, Scientist “E”. CMET Pune, Dr. Shibu John, CEO & Founder, 3D GRAPHY LLP, Founder & Secretary, 3DPERA, Dr. Winstone Deaver, Research Engineer, 3D GRAPHY LLP, Mr. George K John, Business Associate, Engineering & Marine, 3D GRAPHY LLP, Ms. Tejal Modi, Head PR & Communications, 3D GRAPHY LLP & Editor, 3D Graphy News. Presentation was made by Dr. Winstone Deaver, PhD Additive Manufacturing, Research Engineering, 3D Graphy, Dr. Shany Joseph, Scientist “E”, CMET Pune joined by Dr. Sankha Dip Das, Scientist ” E” , Ministry of Electronics & Information Technology, Govt. of India. Title Slide Title: 3D Printing in Electronics and Semiconductors Subtitle: Revolutionizing Military Technology Presented by: Dr. Winstone Deaver, PhD Additive Manufacturing, Research Engineer, 3D GRAPHY LLP, Dr. Shany Joseph, Scientist ” E”, CMET Pune. For: Brigadier Rajesh Verma, Head of Electronics, Military College of Telecommunication Engineering, Mhow Date: 21th August 2024. Introduction Overview of 3D Printing in Electronics and Semiconductors Brief history and evolution of 3D printing in electronics. Importance of 3D printing for the military and defense sectors. Applications of 3D Printing in Electronics Printed Circuit Boards (PCBs) How 3D printing can create complex, multi-layer PCBs. Advantages in rapid prototyping and small-scale production. Antennas and Sensors 3D printing of customizable and lightweight antennas. Integrating sensors directly into 3D-printed devices for field applications. Flexible Electronics Wearable technologies and conformal electronics for soldiers. Examples of flexible displays and sensors used in military gear. 3D Printing in Semiconductor Manufacturing Microelectronics and Semiconductor Devices 3D-printed transistors and microchips: current capabilities and future possibilities. Potential for creating custom semiconductor devices for specific military applications. Integration with AI and IoT How 3D printing supports AI-driven electronics and IoT devices in the field. Real-time data collection and processing through 3D-printed semiconductor devices. Advantages of 3D Printing in Military Electronics Cost Efficiency Reduction in costs associated with traditional manufacturing. Economies of scale for small-batch production. Rapid Prototyping Quick turnaround from design to deployment. Adaptation to battlefield requirements with on-site 3D printing. Customization and Miniaturization Tailoring electronics to specific missions or individual soldier needs. Miniaturizing components to reduce weight and increase portability. Challenges and Future Directions Technical Challenges Material limitations and reliability concerns. Integration with existing manufacturing processes. Future Trends Evolution towards fully integrated 3D-printed electronic systems. Collaboration between military, academia, and industry to advance research. Conclusion Summary of Key Points Reiteration of the benefits of 3D printing in electronics and semiconductors for military applications. Call to Action Encouraging the adoption of 3D printing technologies at the Military College of Telecommunication Engineering. Proposal for a pilot project or further research collaboration. Setting up a 3D GRAPHY HUB in the Institute. Q&A Open Floor for Questions and Discussion This outline can be tailored with specific data, visuals, and examples relevant to Brigadier Rajesh Verma’s interests and the strategic goals of the Military College of Telecommunication Engineering. A proposed a visit to the CMET Pune will be initiated soon for understanding the application and connecting dots for addressing different problem statements using 3D technology. Dr. Shibu John, CEO & Founder, 3D Graphy LLP, Organising Committee Member, 3D GEM 2024 also invited all the respondents in the meeting to participate in the 3D GEM 2024 event held in IIT Delhi on 9th & 10th November jointly organised by IIT Delhi & 3D Graphy.

3D GRAPHY KNOWLEDGE FORUM : ” 3D Printing in Ayurveda “

Pre-event virtual session for 3D Printing in Ayurveda – Main session to be held on 10th November 2024 in IIT Delhi 3D GRAPHY KNOWLEDGE FORUM – is a platform sharing knowledge and information about latest development in 3d technology for different sectors and specialisation. The current knowledge forum was very specific to Ayurveda and its specialisation. The event was initiated by Cmde. Niranjan Khardenavis ( Retd.) Associate Director, 3D Graphy Llp and Dr. Shibu John, CEO & Founder, 3D Graphy Llp, Founder & Secretary, 3DPERA and also the Organising Committee Member 3DGEM 2024 – 3D GEM 2024 is the 4th edition of the International event on 3D Printing & 3zD Visualisation held on 9th & 10th of November in IIT Delhi. IIT Delhi & 3D Graphy is the organisers of the event. A pre- event virtual session was held to update the senior industry leaders in Ayurveda about the prospects of 3D Printing in Ayurveda. The main event will be deliberate about the prospect of 3D Printing in Ayurveda to be held with the 3D GEM 2024 International event held on 10th November in IIT Delhi. We expect all the Ayurved College, Ayurveda Research Centre and Entrepreneurs to join the session to learn the prospects of 3D printing in Ayurveda. Joining the event will be Shri Vaidya Jayant Deopujari, Chairperson, NATIONAL COMMISSION FOR INDIAN SYSTEM OF MEDICINE, Ministry of Ayush, Govt. of India Vaidya Shrikant Kashikar, Principal, Sawakr Ayurved college Vaidya Abhay Kulkarni, Secretary of Ayurveda Seva Sangh, Nashik, Maharshtra, India and Dr. Prakash Katakam, Principal, Indira College of Pharmacy, Nandad. 3D printing in Ayurveda offers fascinating possibilities. For example: Custom Herbal Formulations: 3D printing could allow for precise dosage and combination of herbal ingredients tailored to individual patient needs. This could lead to more effective treatments that align closely with Ayurvedic principles of personalized care. Personalized Medicine: Just as 3D printing is used to create personalized pharmaceuticals, it could be applied to create Ayurvedic remedies customized to a patient’s specific constitution (Prakriti) and imbalances (Dosha). Educational Models: 3D-printed models could be used in Ayurveda education to help students better understand anatomical structures or the physical characteristics of various herbs and plants. This could enhance the learning experience by providing tangible, hands-on tools. These applications show how ancient wisdom can integrate with cutting-edge technology to improve healthcare outcomes and educational processes.

3D GRAPHY KNOWLEDGE FORUM : ” 3D Printing in Ayurveda “ Read More »

3D GRAPHY KNOWLEDGE FORUM – ” Additive Manufacturing for Cochin Shipyard ” A Session sharing the prospects of 3D Printing and Additive Manufacturing for Shipbuilding and Marine engineering.

3D Graphy organised a session on 3D Printing and Additive Manufacturing for the officers of Cochin Shipyard. The session likely focused on introducing these technologies, discussing their applications in the maritime industry, and exploring how they can benefit shipbuilding and repair processes. This type of session would typically cover topics such as rapid prototyping, customized parts manufacturing, and the potential for reducing costs and improving efficiency in shipyard operations. The session was initiated by Mr. George John Kochukaleekal, BE Mech, Chartered Engineer, FIE, FIMarE, FIOV ( Valuation), Certified Lloyd Quality Assurance Auditor for Quality, Safety, Environment, Certified Member Institute Arbitration and Mediation of India. Licensed Marine Chief Engineer from Ministry of Marine Department Singapore. Presently he is the Business Associate, Engineering & Marine, 3D GRAPHY LLP promoting the prospects of 3D Printing & 3D Visualisation for Training, Research and Business with the interest of setting up 3D GRAPHY HUB’s in various organisations and centre’s in India both Engineering and Medical. Since 3D technology is not confined to only one specialisation or sector the scope is immense and it is 3D Graphy’s clear intent to propagate 3D technology across industries. As the credit line of 3D Graphy say’s it all – ” Democratising 3D technology to benefit all” Other team members from 3D Graphy who joined the meeting included Dr. Shibu John, CEO & Founder, 3D GRAPHY LLP, Founder & Secretary, 3DPERA, Organising Committee Member – 3D GEM 2024, Cmde. Niranjan Khardenavis, ( Retd.) Ex- CTO, Indian Navy, Associate Director, Defence & Marine, 3D GRAPHY LLP, Dr. Winstone Deaver, PhD Additive Manufacturing, Research Engineer, 3D GRAPHY LLP, Ms. Tejal Modi, Head PR & Communications, 3D GRAPHY LLP, Editor, 3D Graphy News. Members from Cochin Shipyard and other dignitaries who joined included Dr. K L Simon, Ex Chief Marine Engineer, Ex Principal Surveyor DG Shipping Mumbai, Ex- Chairman Lakshadweep Shipping, Ex-Director/ Eurotech Marine College, Cochin University Science and Technology Marine Engineering college. Presently Chairperson of Maritime University Cochin. 3D printing technologies offer several benefits and advantages for shipbuilding and boat making, making them increasingly valuable in the maritime industry. Here’s how they can be useful: 1. Rapid Prototyping Benefit: Allows shipbuilders to create scale models of ships and boat components quickly. Advantage: Enables faster design iterations, leading to more efficient design processes and reduced time to market. 2. Customization and Complex Geometries Benefit: 3D printing allows for the creation of complex, customized components that would be difficult or impossible to manufacture using traditional methods. Advantage: Facilitates the production of unique parts tailored to specific vessels, improving performance and reducing material waste. 3. Reduced Material Waste Benefit: Additive manufacturing (AM) adds material layer by layer, using only what is necessary. Advantage: Minimizes waste compared to traditional subtractive manufacturing methods, leading to cost savings and a more sustainable production process. 4. On-Demand Production Benefit: Components can be printed as needed, reducing the need for large inventories of spare parts. Advantage: Leads to lower storage costs and faster response times for repairs and maintenance. 5. Lightweight Structures Benefit: 3D printing allows for the creation of lightweight, yet strong, components. Advantage: Contributes to the overall weight reduction of the vessel, which can improve fuel efficiency and reduce operational costs. 6. Enhanced Design Flexibility Benefit: Complex designs that would be challenging to achieve with traditional methods can be easily realized with 3D printing. Advantage: Enables innovative designs that can improve the hydrodynamics, strength, and functionality of ships and boats. 7. Cost-Efficient Prototyping and Tooling Benefit: 3D printing can be used to create molds, jigs, and fixtures needed for the production of ship components. Advantage: Reduces the costs and lead times associated with traditional tooling, making the production process more flexible and cost-effective. 8. Integration of New Materials Benefit: Advanced 3D printing technologies can work with a wide range of materials, including metals, composites, and polymers. Advantage: Allows shipbuilders to experiment with new materials that offer better performance, corrosion resistance, or other desirable properties. 9. Simplified Supply Chains Benefit: The ability to print parts on-site reduces the reliance on complex supply chains. Advantage: Decreases lead times and the risk of supply chain disruptions, which is particularly beneficial in remote or maritime environments. 10. Improved Maintenance and Repairs Benefit: 3D printing can be used to produce replacement parts on demand, even in remote locations. Advantage: Shortens repair times and extends the operational life of vessels by making it easier to replace worn or damaged parts. Overall Impact on Shipbuilding and Boat Making 3D printing and additive manufacturing offer a transformative potential in shipbuilding by enhancing efficiency, reducing costs, and enabling the creation of more innovative and sustainable vessels. As these technologies continue to evolve, their adoption in the maritime industry is expected to grow, further driving improvements in design, production, and maintenance processes. In additive manufacturing (AM), a variety of materials are used depending on the specific requirements of the application. Here’s a look at some of the materials like cupronickel and phosphor bronze, along with others that are commonly used in AM, particularly in industries like shipbuilding, aerospace, and automotive: 1. Cupronickel (Copper-Nickel Alloys) Composition: Typically contains 70-90% copper and 10-30% nickel, with small amounts of other elements such as iron and manganese. Uses in AM: Cupronickel is used in 3D printing for marine applications due to its excellent corrosion resistance, particularly in seawater environments. It’s ideal for parts like propellers, piping, and heat exchangers. Advantages: Corrosion Resistance: High resistance to corrosion in seawater, making it perfect for marine applications. Thermal Conductivity: Good thermal conductivity, beneficial for heat exchangers and other thermal applications. Biofouling Resistance: Reduces the adherence of marine organisms, which is critical in ship components exposed to seawater. 2. Phosphor Bronze Composition: An alloy of copper with 0.5-11% tin and 0.01-0.35% phosphorus. Uses in AM: Phosphor bronze is often used in 3D printing for creating components that require high wear resistance, such as bushings, bearings, and springs. Advantages: Wear Resistance: Excellent wear resistance, making it suitable for moving parts. Fatigue Resistance: High fatigue resistance, beneficial